PR.E.SE. sensors

PR.E.SE. (PRedictive Electrical SEnsors) allow constant wireless monitoring of the temperature in electrical equipment, based on RFID (Radio Frequency Identification) technology in UHF band. They allow preventing and anticipating the trend of overheating of electrical equipment (critical temperature >120°C) due to overload, corrosion, loose connections and difficult environmental conditions and permit predictive maintenance of the electrical insulation, whose aging is particularly influenced by the increase in temperature. The sensors allow improving the performance of the system and extend its life cycle. C.R. Technology Systems has developed this solution in collaboration with Radio6ense, an innovative start-up, born as a spin-off of the University of Roma Tor Vergata (www.radio6ense.com).

Technical features

Digital Technology: digitalized measuring and transmission (possible integration into the SCADA system)

Wireless: tags communicate using electromagnetic fields

Smart functions (eg. RSSI): possibility of integrating additional sensors such as humidity level and vibrations

Extreme stability: thanks to simple debug tracing

In electrical switchgears, sensors are usually planced in critical points: busbar, contacts (fixed and removable) of the circuit-breaker, power cable conection bars

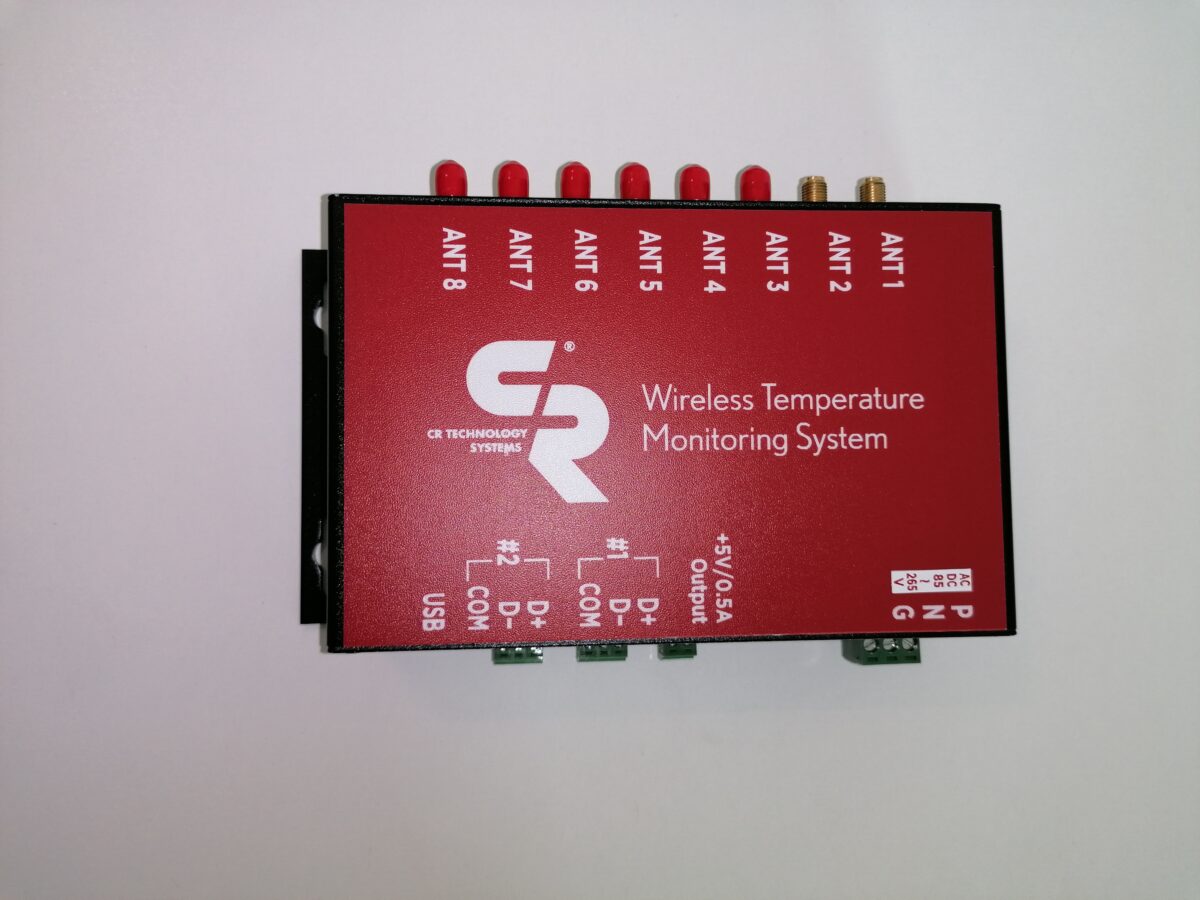

The hardware system includes: sensor, antenna, reader, modbus gateway

Security: transmission is accompanied by CRC Check, without risk of interference

Advantages

Adaptable: tags can be applied to any type of surface and environment, and in any weather condition

Reliable: tags are batteryless and do not require maintenance after their application

Modularity: sensors are equipped with a modular and scalable architecture. A large number of uniquely addressable sensors can be applied

Economic advantage: the technology based on radiofrequency allows lower costs than the traditional ones

Accuracy: sensors with ID prevent reading errors

Retrofit: sensors can be integrated in operational plants, enlarging their lifespan

Greater system efficiency: they allow minimizing system failures, thanks to integration with the IoT to plan predictive maintenance

Tailor-made products: thanks to the different shapes and surfaces of the sensors, and the possibility of integrating them in a variable number according to the customer's needs

Applications

Medium-voltage electrical switchgears

E-House / switching station

Transformation cabins

Mobile substations

Photovoltaic systems

Wind farms

Electricity generation and distribution systems

Related projects to PR.E.SE. sensors

Normal Clad switchgear for electrical power grid

Latin America

Design, manufacturing and supply of n. 24 MV AIS Normal Clad cubicles 13.8kV 2500A 25kA equipped with our wireless and battey-less PR.E.SE. (PRedictive Electrical SEnsors), Power transformers 110kV/34,5kV 28/40MVA with ONAN/ONAF, Power Transformer Protection panel, and customized SCADA system.