The compact electrical substation is a plug-in and pre-assembled solution, that allows reducing installation costs and time on-site. It occupies limited spaces and guarantees the protection of electrical equipment hosted inside it.

Electrical cabins carried out by C.R. Technology Systems can be E-Houses, for the energy distribution, or Transformation cabins. In both cases it is necessary to benefit from all the advantages of new technologies to create a new type of cabin capable of collecting information from the equipment to send alarms and advice, in order to improve their efficiency and life.

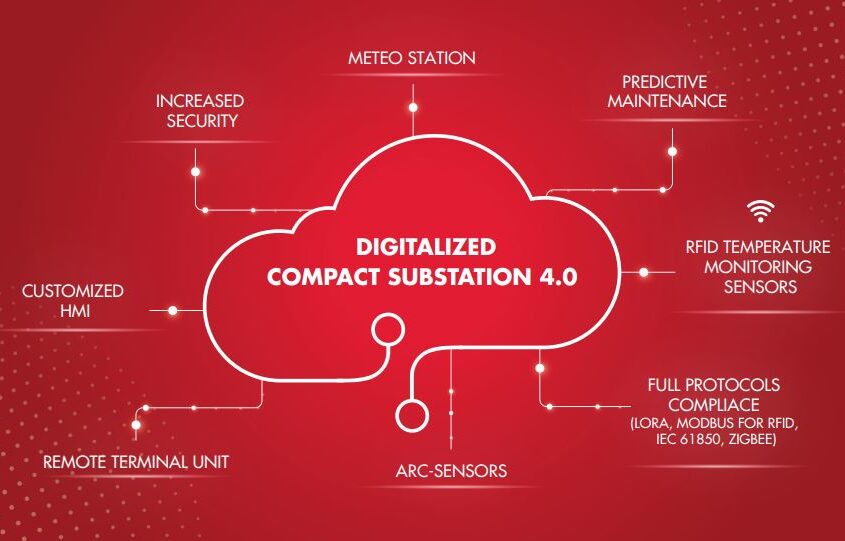

Integrating the electrical cabin with cutting-edge systems and sensors allows many advantages:

Maximize continuity of service

Having modern and flexible electrical distribution plants at the service of one’s business allows companies to optimize their investments through more efficient activity planning. All is possible thanks to a simple and intuitive graphic interface locally and remotely monitored through the Cloud.

Reducing recovery times

Having electrical distribution systems that can be restored quickly and without costly and complex specialist interventions means:

- To minimize economic losses due to the unavailability of the plant in the event of a breakdown

- To better plan personnel activities specialized

- To minimize the time in which the plant is exposed to risk conditions

- To increase the speed and simplicity of restoring normal operating conditions

Maximize equipment life-cycle

Thanks to the collection of information, received from the sensors predictive maintenance allows you to act promptly on the system and keep it in good health.

Having durable electrical distribution plants makes it possible to amortize company investments over a longer period of time; improve energy consumption, raw materials, and the availability of components and spare parts if necessary.

Remote monitoring

Thanks to SCADA systems, it is possible to remotely monitor the electrical plant. Through the acquisition of data, the software can promptly identify possible failure and, more in general, any type of event.

Da un punto di vista ecologico, la digitalizzazione della cabina elettrica garantisce una riduzione dell’impatto ambientale e un risparmio fino all’80% del cablaggio. Inoltre, consente di ridurre il numero di trasferte in sito da parte dell’operatore, grazie alla connessione da remoto.

Customized HMI interface

For optimal remote intervention, it is important to be able to customize the interface.

The main goal of the user interface is to allow the operator to view data on operations and control the plant from a single room, thus having a better overview of the plant. Operators can use HMI to manage any alarms quickly.

Moreover, advanced technologies such as the IoT and data analytics technologies, are more and more integrated into the human-machine interface.

Technological sensors

Main sensors that C.R. Technology Systems implements are PR.E.SE. sensors. They allow the temperature and humidity monitoring 24/7 of all components, based on the RFID (Radio Frequency IDentification) technology.

These sensors have been studied and developed by C.R. Technology Systems, with the help of the start-up Radio6ense, and make it possible to monitor the system in an innovative and economic way, compared to other technologies on the market.

Internal arc sensors detect faults caused by internal arcing and act promptly to stop generalised damage to the system. This quick-detection system uses light-wave sensors that measure the luminescence generated by the arc in order to ensure the tripping of circuit breakers on the load or power side, minimising the duration of the arc and isolating the damaged points.

The internal arc sensors detect faults caused by internal arc and act promptly, to stop a generalized damage to the installation. This fast detention system uses light wave sensors that measure the luminescence generated by the arc to ensure that load or supply side circuit breakers trip, minimizing arc flash duration and isolating fault points.