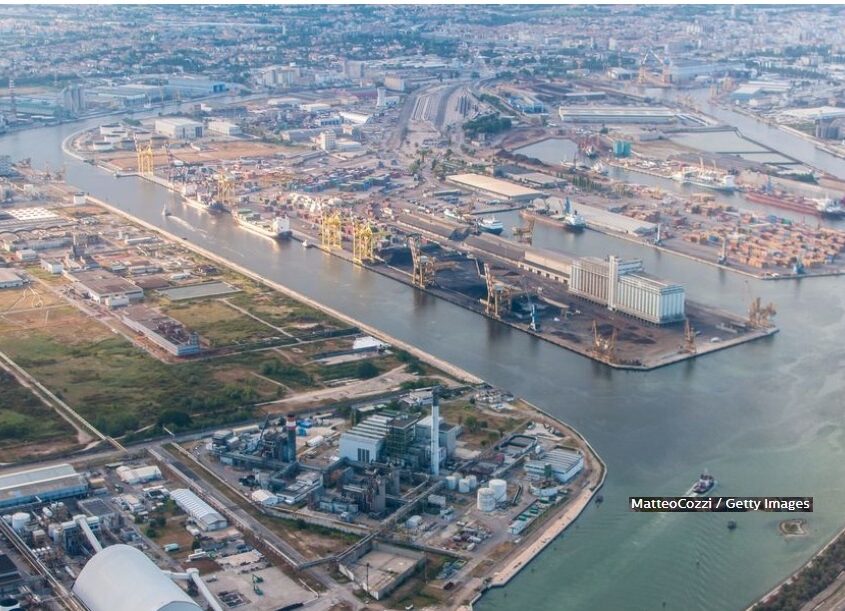

The project involving n. 2 electrical substations, addressed to a plant in Marghera Levante port in Venice, represents a new challenge for C.R. Technology Systems.

This work is part of the national energy transition program which sees the redevelopment of major infrastructures such as those of Marghera Levante.

The international experience and the transversal skills of the Engineering Hub of C.R. Technology Systems have contributed to this complex project, unique for its innovation and technological features, which will consist of:

N. 2 E-House, compact substations STC-Box, equipped with GIS 245kV mounted on skids to enable cable passage. We are talking about big modular structures with the following features: length 13.3 meters – width 5.2 meters – height 7.5 meters. These features will guarantee high-quality protection standards (degree of protection IP, earthquake-resistant, IK degree) keeping easy and simple conduction and maintenance, ideal to contain the main components such as gas-insulated substations.

E-Houses will be accessible via stairs that lead to a walkway, from which it will be possible to access the cabins. Furthermore, they will have a specific central cover and are equipped with withdrawable side supports and panels, in order to allow maintenance operations of electrical switchgears.

The two Skids that will support the electrical panels will be raised from the ground by 1.5 meters, in order to facilitate fastening of high voltage cables. Moreover, the structural supports that will include the internal electrical equipment will weigh respectively 13.5 tons and 19 tons and are built in HE – IPE – UPN beams in steel S355JR, according to EN10025 standards.

Skids, stairs and walkways, totally designed by our engineers, will be made with a hot galvanizing treatment. These measures have made our compact substations more resistant to strong winds and seismic shocks.

The collateral non-bearing panels will be made of mineral fiber and will be resistant to flames; while the side panels will be in EI 60 material with a thickness of 80 mm, where:

E Hermeticity, tight to flames and hot gases

I Thermal insulation

60 minutes for which the hermetic and insulation performance of the panel is guaranteed

The structural covering panels in REI 90 type will have a thickness of 80 mm, including mechanical Resistance (R) to EI characteristics. The panel will maintain its hermeticity, thermal insulation and resistance in the event of a fire for 90 minutes.

In order to prevent the evolution of a fire inside the structure and, at the same time to report its presence in a timely manner, the E-houses will be equipped with a latest generation smoke detection system.

The lower closing panels will be painted in aluminum to ensure the protection and safety of high-voltage cables against external agents.

All switchgear covers will be in press-bent Magnelis sheets, coated with anti-drip a2S1d0 paint for marine environments and fixed with stainless steel screws.

Magnelis is a metallic, steel-coated product that uses a chemical composition of 93.5% zinc, 3.5% aluminum and 3% magnesium. Thanks to its long-life cycle and its high-corrosion resistance, this metal is particularly suitable for saline environments and subject to hostile atmospheric agents such as the one in which our electrical substations will be installed. Furthermore, Magnelis is totally recyclable, so it can be a valid alternative to more polluting materials.

The most efficient and environmentally friendly technology and materials with low emissions will contribute to the goal of making this structure in Marghera Levante not only more functional, but also more sustainable.