The degree of protection of an electrical switchgear is a parameter defined by the international standard CEI EN 60529 (IEC529 ex CEI 70-1) which establishes the sealing effectiveness of enclosures for electrical material with rated voltage up to 72.5 kV, against the intrusion of objects, dust, liquids or accidental contact.

It consists of two digits:

- The first indicates the degree of protection against the ingress of solid materials, such as dust or shavings.

- The second is the degree of protection against the ingress of liquids, such as drops or jets of water.

The degree of protection IP must be chosen in relation to the switchgear final application.

In general, the IP of indoor switchgear must be at least IP2X, while for outdoor switchgears IPX3.

It must be taken into account that the IP degree affects the ability of the electrical switchgear to dissipate heat: the higher the degree of protection, the less it manages to dissipate it and ad-hoc solutions will be needed to ensure that natural or forced ventilation is guaranteed.

Degree of protection in removable parts

It is possible to remove or extract moving parts in installed switchgear, in the following situations:

- Removal of the withdrawable part of a component (eg: circuit-breaker, contactor, disconnector) for repair, control or maintenance;

- Removal of a fixed part (eg: panels, covers or bases) during electrical works, such as the implementation of new lines or the replacement of existing cables.

Mining applications

The standard does not specify which IP protection degree to adopt according to the different environments in which the switchgear is inserted, with the exception of those subject to explosion hazard (CEI 64-2, CEI 31-35).

In mines and other dusty environments of heavy type (eg: ferrous dust), it is recommended the use of cubicles with a protection degree equal to IP65 or IP54.

IP6X means that the switchgear is completely protected against the infiltration of dust, while IPX5 indicated that full protection against water jets from all directions is guaranteed.

Thanks to its features, the Normal Clad electrical switchgear designed by C.R. Technology Systems can operate above 4000 meters a.s.l. and in underground environments, subject to hostile conditions.

Technical features of IP65 Normal Clad switchgear (up to 40.5kV)

The Engineering Hub of C.R. Technology Systems studies and develops Normal Clad electrical switchgears with a degree of protection IP65, now mainly supplied and tailored to mines situated in the South America area.

The protection of the switchgear is ensured by a sealed metal casing with a watertight gasket, while the casing is designed to protect a single cubicle and the modular components of the structure are sealed together to ensure a hermetic seal.

The switchgear is raised from the ground, allowing both a distance from the muddy ground (or subject to potential flooding) and cable entry from below. Alternatively, the cable ingress can be located laterally or placed on top of the cell itself.

The sloping roof has the function of protecting the components against rain and drops that characterize humid environments, while an additional front roof is designed to protect the operator.

Access to the switchgear is possible through the frontal door, equipped with a key or padlock.

To ensure greater visibility, our paintings intended for mines are usually in orange (open to any color code required).

It should also be emphasized that the correct functioning of the IP degree of our panels is guaranteed by specific tests, which must be carried out:

- Tightness test of gaskets and doors in closing and in operating conditions

- IP test without the aid of voltage presence, unless requested

Case study: Normal Clad IP65 for Peruvian mine

In the province of Yauyos, we have designed, constructed, and supplied n. 7 medium-voltage Normal Clad switchgear cubicles 24kV 630A 31.5kA and 17.5kV 1250A 31.5kA, with IP65 protection degree, with the aim of increase the electricity supply of a mining plant.

The full project details at the following link:

IP Degree of protection tables

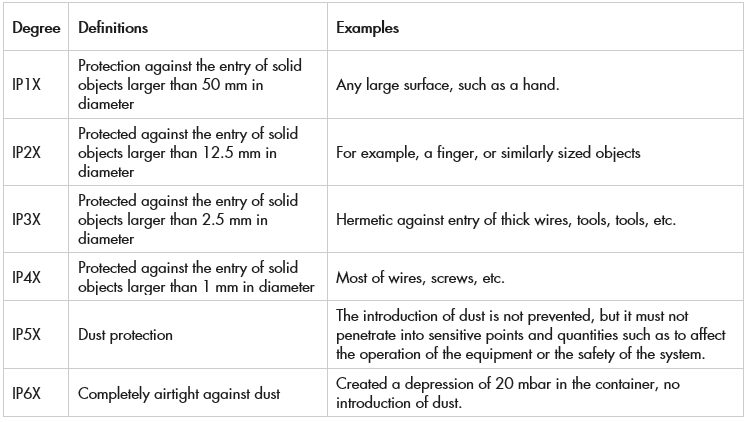

IP degree of protection, EN 62208 – EN 60529

First digit – Protection against ingress of solid materials

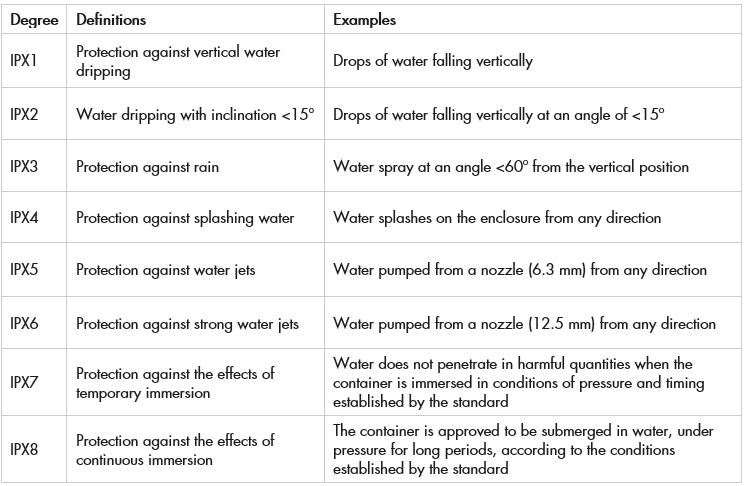

IP degree of protection, EN 62208 – EN 60529

Second digit – Protection against ingress of liquids